introduction

Granofiber

Granofiber introduces an innovative approach to coloring PVC compounds (both flexible and rigid), offering a distinct alternative to traditional methods that rely on pigment powders or colored masterbatch granules.

Unlike conventional pigment powders, Granofiber is dust-free, has a high color concentration, and comes in a filament-like form, making it an excellent choice for higher-quality production, reduced contamination in the workplace, and easier handling for operators.

The use of pigment powders or masterbatches in the production of colored PVC compounds has both advantages and disadvantages, which are briefly outlined in the comparison table below.

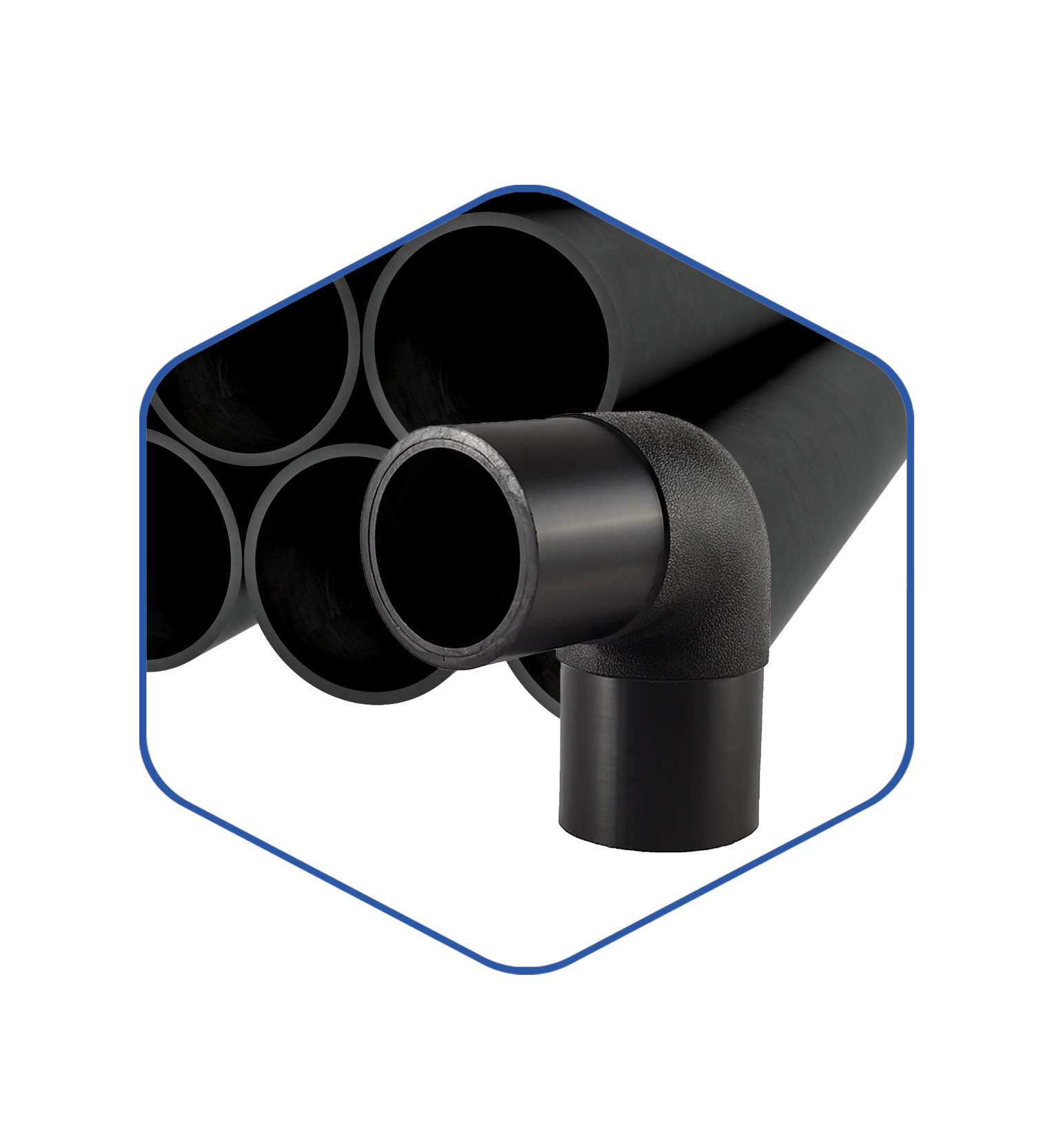

Providing UV resistance for polymer products is one of the primary applications of industrial carbon black.

The use of Granofiber in the production of polyethylene pipes enhances UV protection due to its high carbon black content, significantly improving the durability and service life of these products.

With a carbon black content of 55%, Granofiber allows for lower dosage levels compared to conventional masterbatches, while still improving the mechanical properties and surface quality of the polyethylene pipes.

One of the key features of Granofiber is its compatibility with extrusion side feeders, allowing it to be dosed directly during the extrusion process.

This enables manufacturers to use uncolored PVC compound granules in combination with Granofiber to produce a variety of products—such as UPVC profiles, insulation, and cable sheathing—in the desired color.

Coloring plastic parts during the injection molding process is one of the key applications of Granofiber.

Due to the absence of a polymer carrier, Granofiber is a versatile and efficient choice for producing a wide range of parts using various polymers.

It can be used with PVC, polyethylene, polypropylene, and other polymers, offering broad compatibility.

Thanks to its high carbon black content (55%), Granofiber requires a lower dosage compared to traditional masterbatches, while still enhancing mechanical properties and surface quality.

Another significant advantage is the reduced time and material needed for purging the injection cylinder and screw, making the process cleaner and more efficient.

جزئیات بیشتر

Granofiber

No FAQs available.

Technical Specifictions